A temperature-controlled clean room for pharmaceuticals

Baxter International Inc., a prominent American multinational healthcare

company headquartered in Deerfield, Illinois, is dedicated to providing

essential healthcare solutions. In 2023, Baxter's 3PL partner, Dawn India,

reached out to EcoYou with a specific project requirement.

A temperature-controlled clean room for pharmaceuticals

Baxter International Inc., a prominent American multinational healthcare company headquartered in Deerfield, Illinois, is dedicated to providing essential healthcare solutions. In 2023, Baxter's 3PL partner, Dawn India, reached out to EcoYou with a specific project requirement.

- Home

- »

- Case Studies

- »

- A temperature-controlled clean room for pharmaceuticals

The Requirements

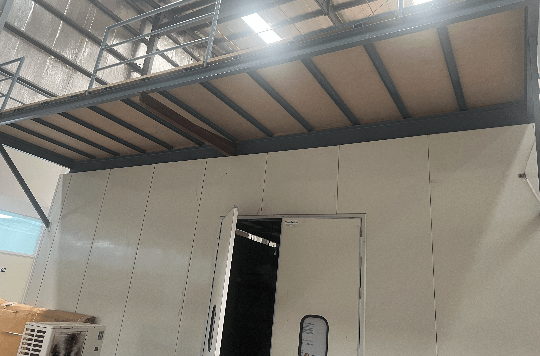

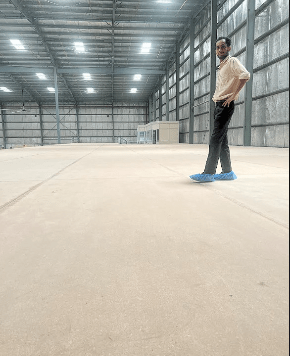

- The project entailed creating a clean room and a temperature-controlled enclosure for the storage of Baxter's pharmaceutical products, covering an area of 12,000 square feet.

- Strict temperature control was essential, with the pharmaceutical products requiring storage at temperatures below 20°C.

- Safety and efficiency were crucial factors as optimal facility usage would enhance space management. was paramount, necessitating the use of fire-retardant materials.

- The customer had a stringent timeline and sought to initiate the facility in less than four weeks.

The Solution Implemented

- Despite the challenging requirements, EcoYou leveraged its extensive experience from various projects to provide the optimal solution.

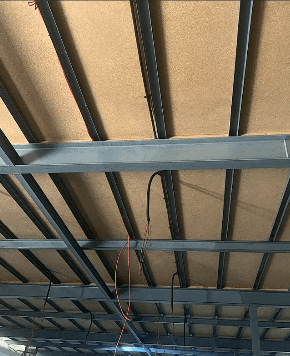

- EcoYou's technical teams employed their state-of-the-art solution, EcoDek, on the ceiling. This innovation allowed for the creation of a load-bearing mezzanine with a capacity of 500 Kg UDL. An insulation sheet was used to cover the joints, enhancing thermal performance.

- Customized sizes, tailored to the project's layout, were delivered swiftly, reducing lead times.

- Following project execution, HVAC systems were installed and assessed for thermal resistance, and the materials' load-bearing capabilities were tested, resulting in satisfactory outcomes.

The Solution Implemented

- Customized design to meet specific needs

- Construction of an office and warehouse on a support structure of racking

- Quick project initiation and installation by the EcoYou team

- Ground +1 structure with over 12,000 sq ft of wall area

- Deployment of a multi-disciplinary team of engineers for fast installation and ramp-up

- Best-in-class design, supply, and installation provided

The Result

EcoYou’s solution successfully met the project’s complex requirements.

Traditional materials like PUF panels and concrete floors were avoided in favor of EcoYou’s innovative solutions.

The project achieved a substantial cost reduction of 30%.

The endeavor contributed to sustainability by reducing the use of high-carbon materials like concrete. Additionally, it generated additional income for farmers, aligning with EcoYou’s commitment to a greener future.

Featured Products

EcoFreeze

EcoFreeze made using composite board “EcoBoard” engineered specifically to meet temperature control…

EcoRak

EcoRak made using composite board "EcoBoard" engineered specifically to meet storage needs in Storage ...

EcoDek

EcoDek is a composite panel made with "EcoBoard" engineered specifically to meet industrial flooring needs....